Prefabricated Modular Panel Buildings

Explore the possibilities with Campacx Prefab Buildings. We offer versatile, sustainable, and custom-designed prefabricated structures.

Prefabricated Modular Panel Buildings

What is Prefabricated Buildings?

Prefab buildings are structures that are produced in a factory environment, taking into account criterias such as ease of transportation, assembly, and reduction of processes. Structural elements like wall panels, intermediate floor chassis of multi-story buildings, and roof trusses are partially assembled in the factory and then transported to the installation site for final assembly.

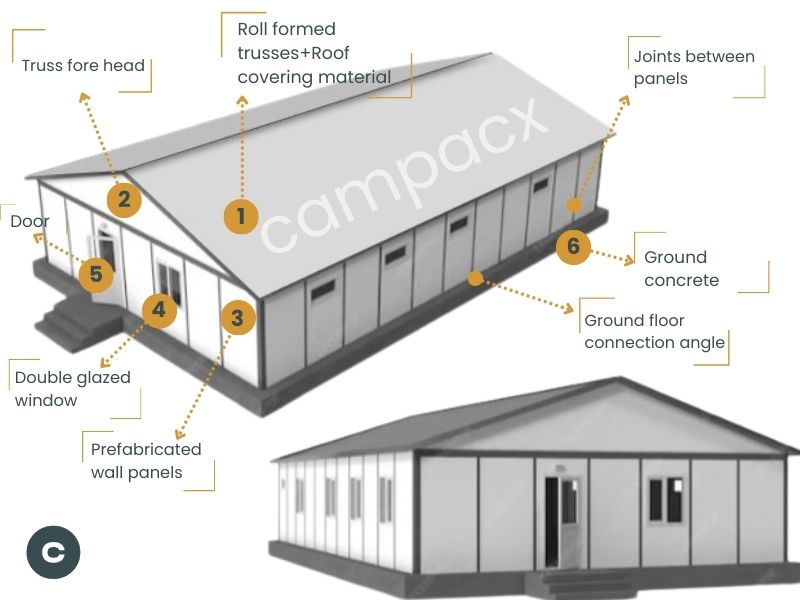

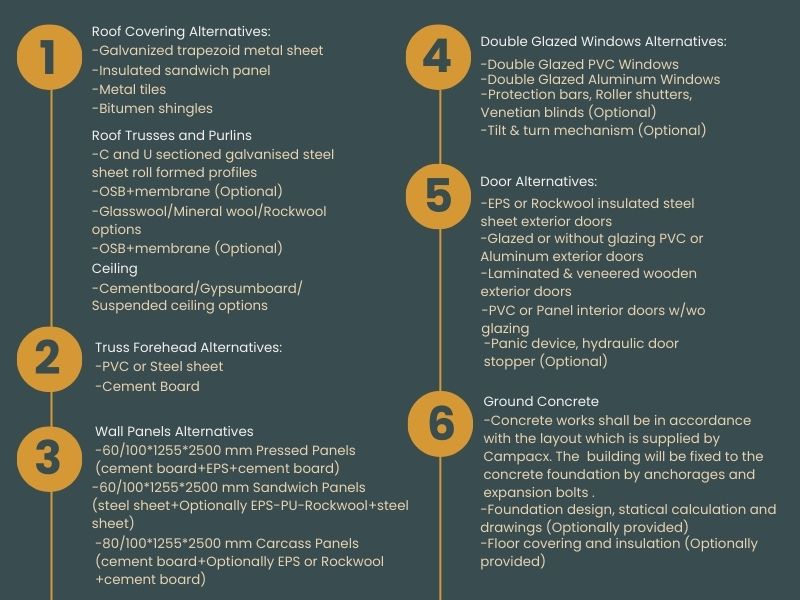

Prefabricated Building Components

Brief Prefabricated Building Technical Specification

Campacx takes into account project inputs in prefabricated buildings (such as climatic data, building purpose, local regulations, technical specifications and requests), and offers prefabricated building alternatives consisting of load-bearing or non-load-bearing walls, such as prefabricated worker camps, prefabricated hospitals, prefabricated buildings that best suit the customer's needs. It supplies public buildings such as schools, prefabricated offices, prefabricated emergency residential buildings, prefabricated military buildings and prefabricated houses.

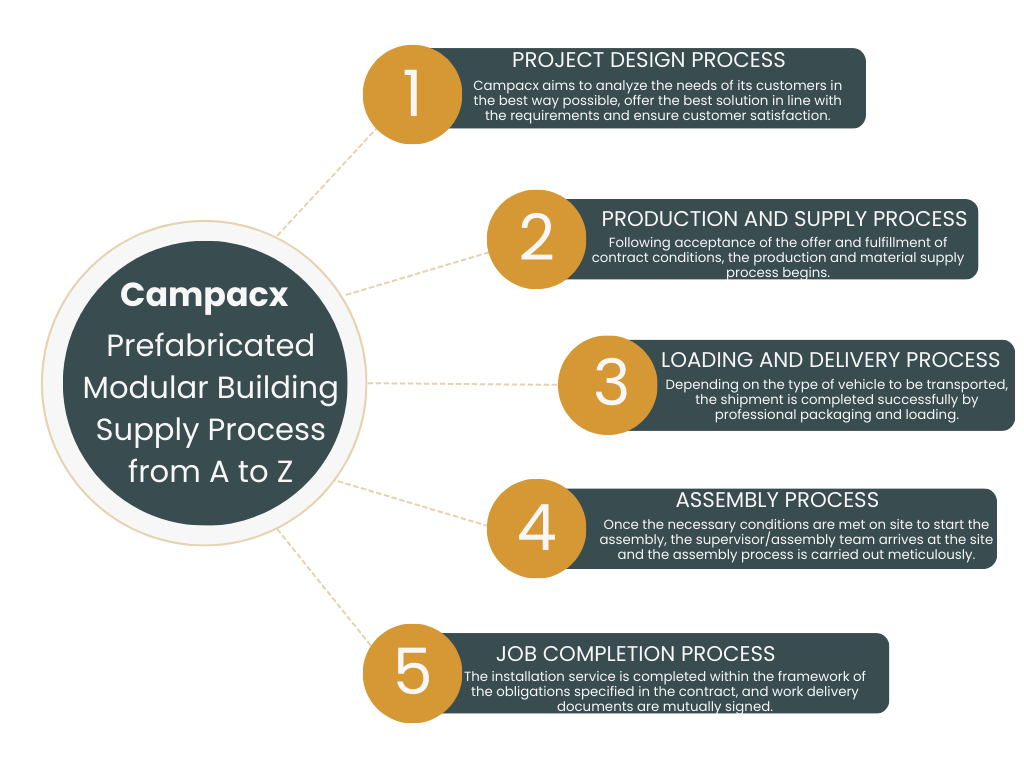

Campacx Prefabricated Modular Building Supply Process from A to Z

1-Project Design Process

At this stage, there are 2 alternatives;

In the 1st alternative, the customer shares the architectural works prepared in line with his needs with our team, and a statical study and cost analysis is carried out by taking into account the climatic data of the region where the project will be carried out, such as snow load, wind load, and data such as the carrying capacity of the base and intermediate chassis to be determined within the framework of the restrictions of the regulations in line with the purpose of use of the building. The offer is prepared.

The 2nd alternative, the customer can receive the service of preparing the preliminary architectural project from Campacx within the scope of the project, if it is a workers' camp, taking into account the number of users and the list of needs. After approval by the customer, the cost and bidding process of prefabricated modular buildings is completed, taking into account the above-mentioned inputs.

Campacx aims to analyze the needs of its customers comprehensively, providing optimal solutions in alignment with requirements, and ensuring customer satisfaction. Within this framework, the following factors can be highlighted as key considerations for choosing prefabricated modular buildings comparing to containerised units solutions.

- The project's duration as a determinant factor:

For projects lasting more than 1-2 years, the activation of comfort conditions for the labor camp or building users, coupled with the ability to differentiate the technical specifications of the elements constituting prefab buildings, and the long-term cost advantages they offer, make prefabricated panel system modular structures a preferred choice.

- Permanent or temporary nature of the building:

When the intention is to construct the building as a permanent prefabricated structure based on its purpose of use, the diversification of design and material alternatives becomes crucial. Considering the importance of climatic data in the statical calculations of buildings and taking into account long-term costs, prefab modular buildings, offered by Campacx, become the preferred option compared to modular containers.

- Cases where project technical specifications are decisive:

In instances where the technical specifications requested by authorities within the scope of a tender necessitate design and production flexibility, the preference leans towards prefabricated modular panel structures.

- Situations where building square meters and spans increase:

Compared to modular container systems, modular prefabricated building solutions allow for the design of larger spans without columns, offering particular advantages. They are especially favored in camp environments, cafeteria structures, open offices, and buildings intended for recreational use.

For a more detailed analysis of your projects, please feel free to get in touch with us.

Campacx carefully analyzes the inputs of your project and offers sustainable, environmentally friendly and customized turnkey prefabricated building solutions.

Turnkey supply;

- *Project design and engineering service (preparation of static calculations and production files),

- *Project management and planning,

- *Production and material supply,

- *Providing logistics services (sea, road, air, etc.),

- *Providing assembly services (with supervisor and/or assembly team),

- *Supply of all kinds of furniture and equipment (supply of furniture to buildings such as offices, dormitories, dining halls, infirmaries)

- *After-sales support

2-Production and Supply Process

Following acceptance of the offer and fulfillment of contract conditions, the production and material supply process begins. Simultaneously at this stage, it is expected that the customer has received/is receiving the necessary legal permit processes, the concrete will be poured in the field in line with the foundation concrete plan provided by Campacx, and the field conditions will meet the conditions specified in the contract for the supervisor/installation team to be sent by Campacx.

3-Loading and Delivery Process

At this stage, prefabricated building materials produced in line with customer demands are disassembled, packaged with safe packaging sensitivity depending on the mode of transportation, and loaded into the cargo container/truck. Shipment is made by Campacx after Türkiye customs procedures are completed.

4-Assembly Process

Once the customer confirms that the necessary conditions to start the installation are met, the supervisor/installation team is sent to the area where the installation will be carried out. Assembly phase of prefabricated modular buildings;

- *Site assembly of prefabricated building materials sent disassembled,

- *Electricity, plumbing, fire equipment, if any, CCTV system, heating-cooling system, etc.

- *Putty and paint process,

- *Includes furniture assembly processes.

5-Job Completion Process

The installation service is completed within the framework of the obligations specified in the contract, and the work delivery documents are mutually signed. The job delivery is completed successfully.

Contact Us

Get in touch

Contact us today to discover how Campacx can transform your space with our customized modular building solutions. Let's discuss how our services can meet your unique needs.